How does the lubricant change between different compressor types?

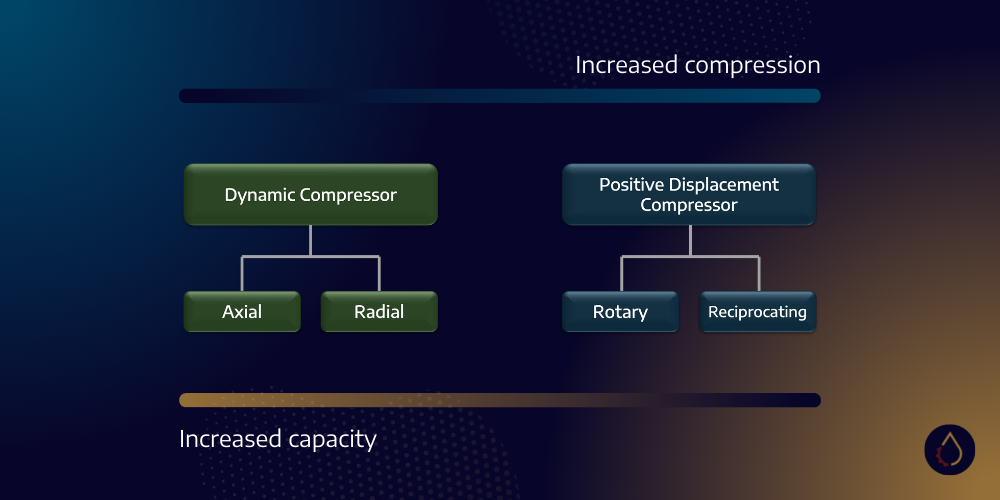

As an application, compressors are unique due to their variability – they present as a wide array of compressor types (centrifugal, axial, vane, reciprocating, oil flooded screw, oil free screw) etc. Because of this, there are a dizzying array of compressor oils and it can be difficult to understand the differences in formulations.

The Changing Face of the Compressor Industry

In the late 1990s you could also look at the US market for reciprocating compressors and approximately 80% of compressors used in light industrial and commercial applications were reciprocating compressors. A minority of approximately 15%, were screw compressors.

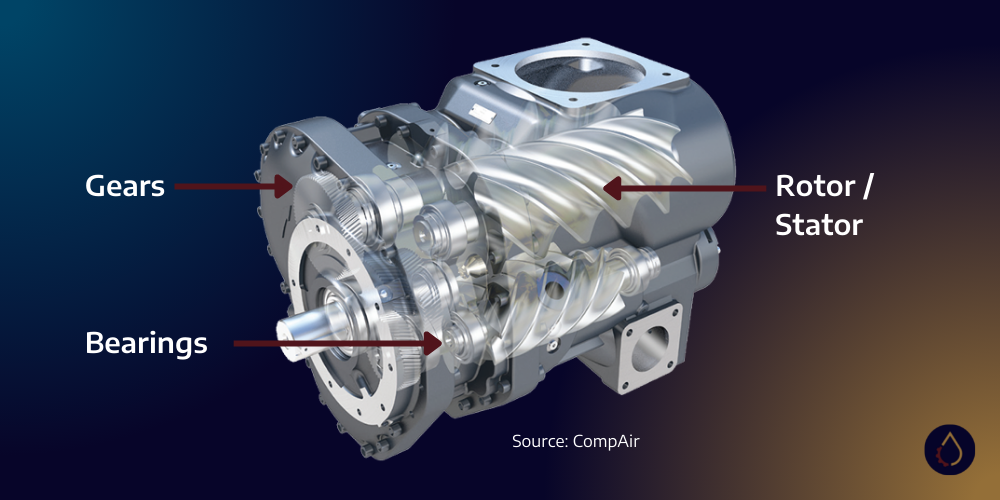

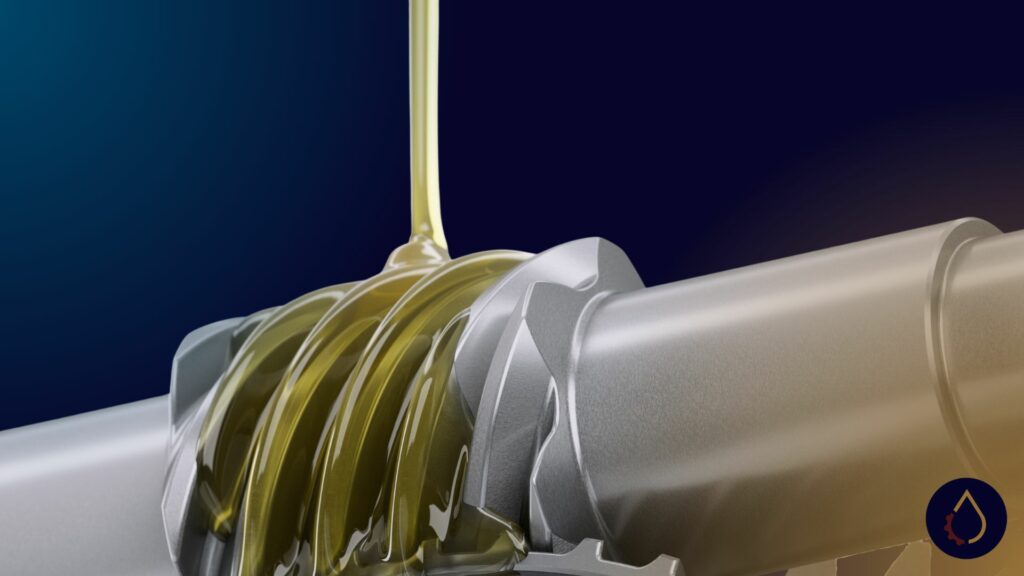

As computerized machining & welding plus other manufacturing technologies were adopted, the reciprocating compressors retreated. By 2020 the screw compressors comprised 80% of volume demand for both compressor machines and lubricants. The predominant operating advantages of screw compressors are far fewer moving parts compared with their reciprocating cousins, and effectively no contact between the stator and the rotor.

The components of a screw compressor are relatively simple and easy to maintain; there are two sets of bearings on each scroll, two fluted casting that which interact with each other, and the spring-loaded valve that controls the pressure to the pressure vessel. This device is much simpler than a reciprocating compressor which has a complexity closer to an internal combustion engine.

While screw compressor may be sold at a price premium there are less frictional movements to manage; screw compressors can last on average 70,000 hours between rebuild cycles. With reciprocating compressors, that number could be as low as 10,000 hours.

Lubricant Requirements

For all compressors, the lubricants must:

- Protect moving components

- Remove and distribute heat

Screw compressors have one additional requirement:

- Seal (between the rotor and stator)

It could be argued that the lubricant acting as a gasket also occurs between the piston rings and cylinders in reciprocating compressors, however in screw compressors this is more important. In centrifugal compressors designed for low compression but high volume the lubricant system is often separated completely from the compressed gases.

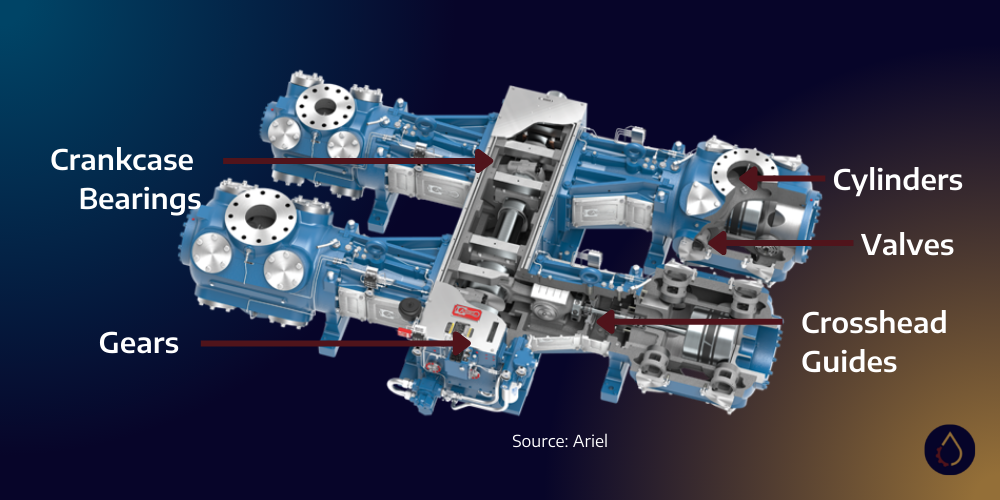

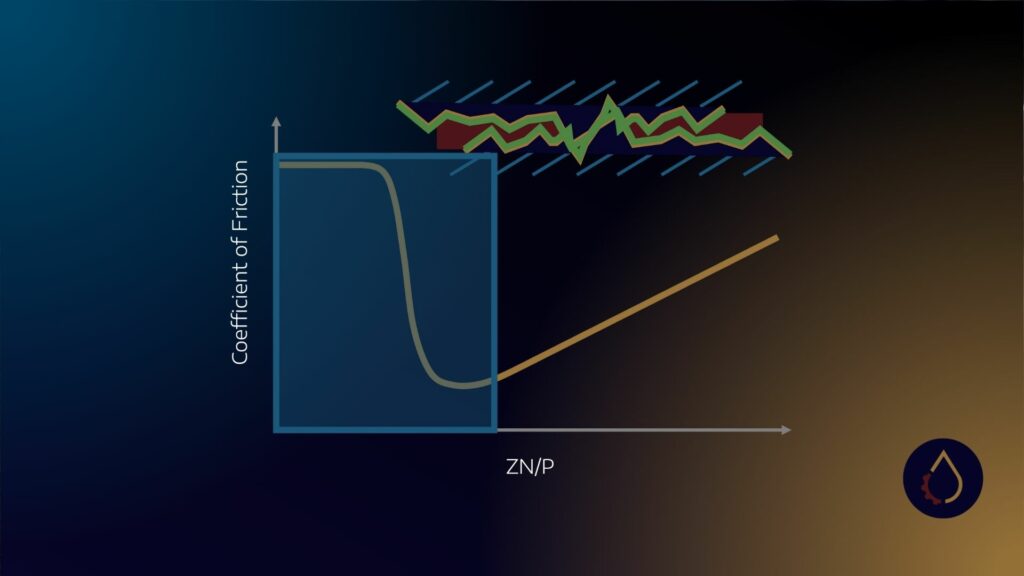

The components that are lubricated also have an effect on the expected lubrication regimes. While screw and centrifugal compressors spend the majority of their operational life in the elasto/hydrodynamic environment, the piston/cylinder combination in a reciprocating compressor will spend a significant portion of its operating life in the boundary/mixed regime.

The final major difference in lubricant requirements is the discharge temperature of the compressors, which in turn determine lube oil temperature. The majority of heat in a compressor application comes from compression, so the higher the compression ratio, the more heat is expected. As a result, screw and centrifugal compressors tend to operate at lower temperatures (90oC – 130oC) versus reciprocating (130oC +).

Base Oil Selection

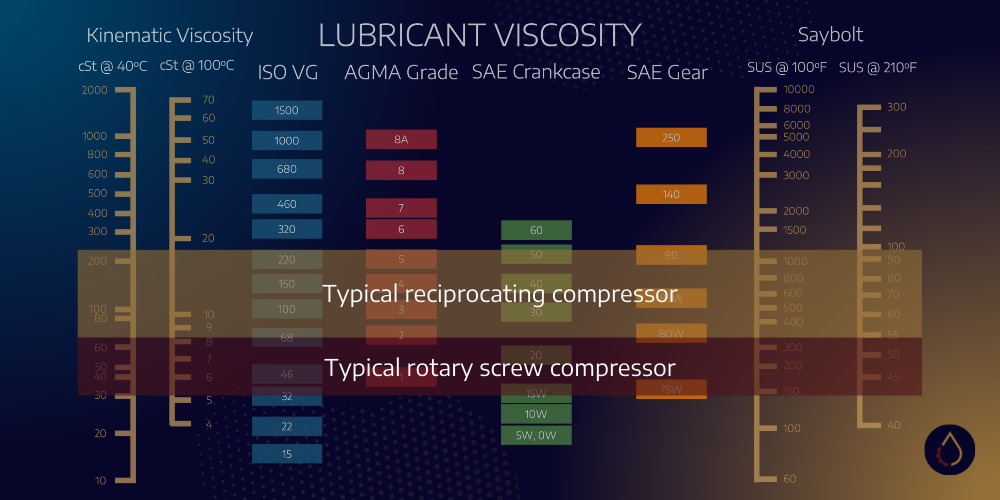

For a screw compressor the viscosity is generally around ISO 46 ISO 68. This is primarily the range for optimal sealing between the rotor and stator; the air bubble travels through the flutes and the screw compresses at a ratio of approximately 10-1. Therefore the lubricant film between the rotor and stator is essential for the operation of the compressor. Centrifugal applications are similarly very lightly loaded, driving ISO VG ranges of 32 – 46.

The viscosity range for a reciprocating compressor more closely mirrors that of an internal combustion engine – with viscosities of ISO 68 – 220 (equivalent to SAE 30 to SAE 50) to adequately lubricate the expensive, and difficult to maintain crankcase bearings.

The base oil type is largely determined by the chemistry of the process gas, however beyond this the operating temperature drives base oil selection. Viscosity index is less of a factor given that industrial compressors are typically not subjected to large variations in ambient temperatures (and if they are, can have lube oil heaters installed to manage), so this opens up a range of base oil types from Group IV and V that exhibit excellent stability at high temperatures, notably the PAOs, POEs and ANs.

With the appropriate selection of base oil type, screw and centrifugal compressor oils can survive three years without an oil change, while reciprocating oils can last 12 months when properly maanged.

Additive Package Selection

As a general rule the compressor oils are lightly additized. Most of the performance is derived from the base oil and the environment does not require EP-style additives or significant detergent/dispersant packages.

For screw and centrifugal compressors some level of antioxidant is required to manage the effects of high discharge temperatures on the oil system. Adequate AO will extend oil life as much as possible. Rust and corrosion inhibitors are also included to prevent negative chemical degradation of the machine components. However, as the majority of the lubrication is elasto/hydrodynamic there is very little antiwear required.

The boundary lubrication experience at the cylinder and pistons of a reciprocating compressors require a more significant antiwear package – again this aligns broadly with the requirements for combustion engines.

Key Takeaways

As an application, compressors are unique due to their variability – both in terms of machine types and the process gas. As a result, compressor oil product ranges often exhibit a wider selection than for example, the gear oils. However, if you understand the reasons behind the variance the selection of a compressor oil becomes a relatively trivial exercise.

Responses